UCHIDA AeroDieCut

Feed Unit

The patented “Tri-suction feeder” ensures

consistent paper feeding. The feeding unit

equips an ultra-sonic sensor for double

feed detection, and a cut-mark sensor to

compensate image shift.

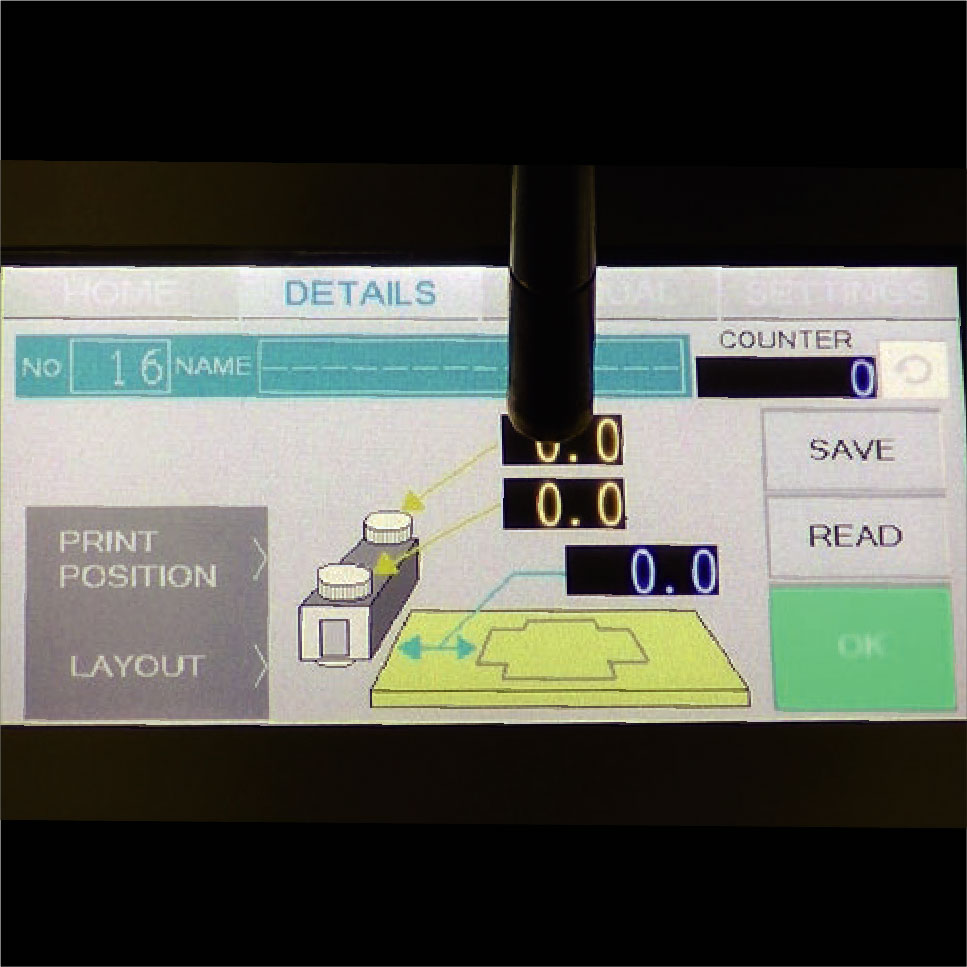

Easy touch screen operation

settings and operation easy. 100 Job

memories can be stored in the machine.

Main Unit (Press unit)

The main press unit uses patented “moving

press rollers” mechanism to press the paper. This makes the die cutting process

much quieter and power efficient than

conventional die cutters

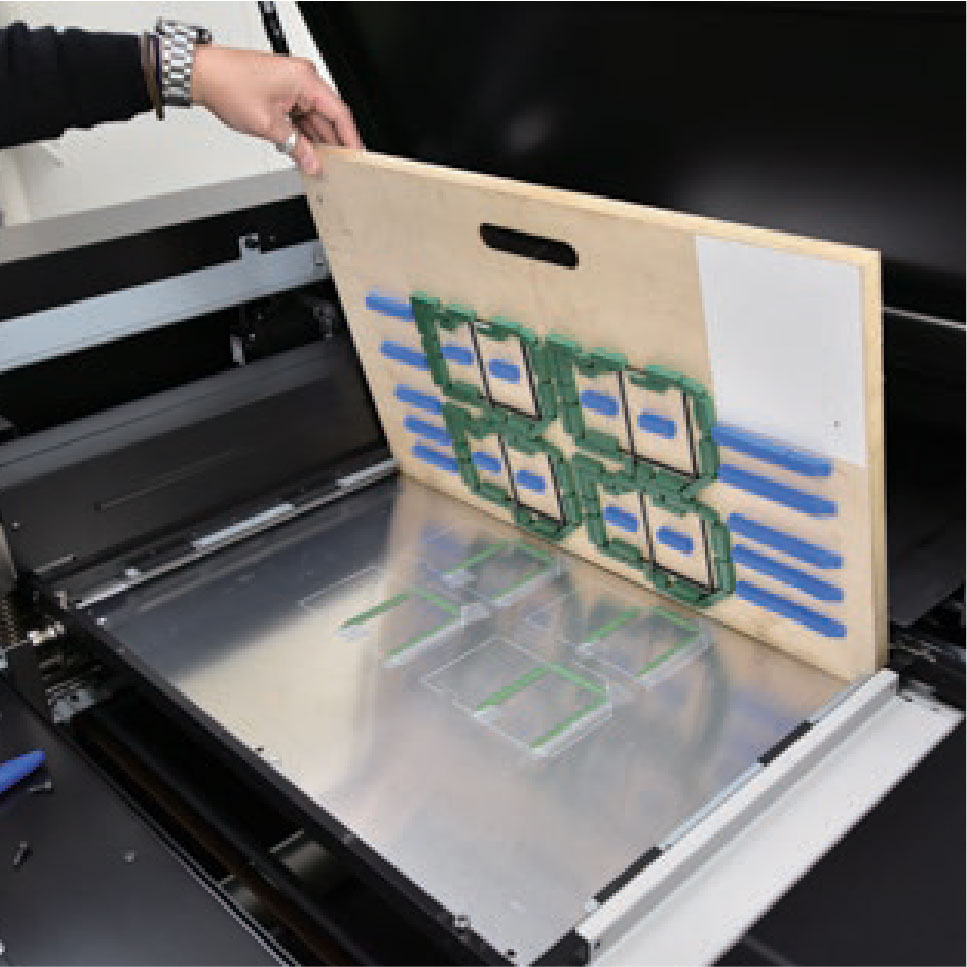

Multiple-up applications

4. Multiple-up applications

The AeroDieCut features step & repeat

function to finish multiple-up applications,

which helps saving the cost of dies.

Optional separator & conveyor delivery

The optional separator deflects wastes

into a waste bin as the die-cut paper is

delivered. (Depending on layout)

The optional conveyor delivery table makes

collecting process more efficient.

Various applications

The AeroDieCut can cut, crease, and

perforate on a print in a signle pass. It turns

your prints into a variety of applications,

such as cards, seing tags, boxes, envelops,

shelf talkers,